Automated Composite Wall Panel Equipment

Buy Automated Composite Wall Panel Equipment which is of high quality directly with low price. As a professional manufacturer, Libo Machinery is willing to provide you with automated composite wall board equipment. We will provide you with the best after -sales service and timely delivery. And adopt advanced safety protection measures, such as safety doors, safety sensors, etc., can effectively ensure safety in the production process.

Send Inquiry

What is light wall board?

Lightweight wall plate is a new type of building material. It uses raw materials and other raw materials such as light material, cement, gypsum, cellulose and other raw materials. It has the advantages of light weight, high strength, sound insulation, insulation, fire prevention and other performance advantages. Lightweight wall plates can be used for the production of building components such as interior walls, exterior walls, partition walls, ceilings, and slabs, which can effectively improve the safety, comfort and environmental protection of the building.

Features:

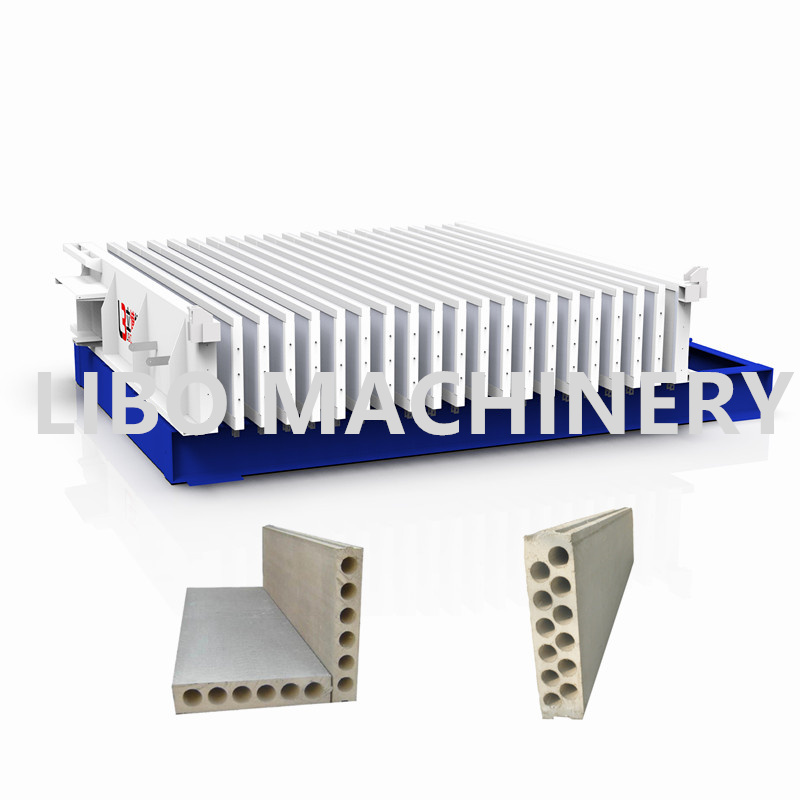

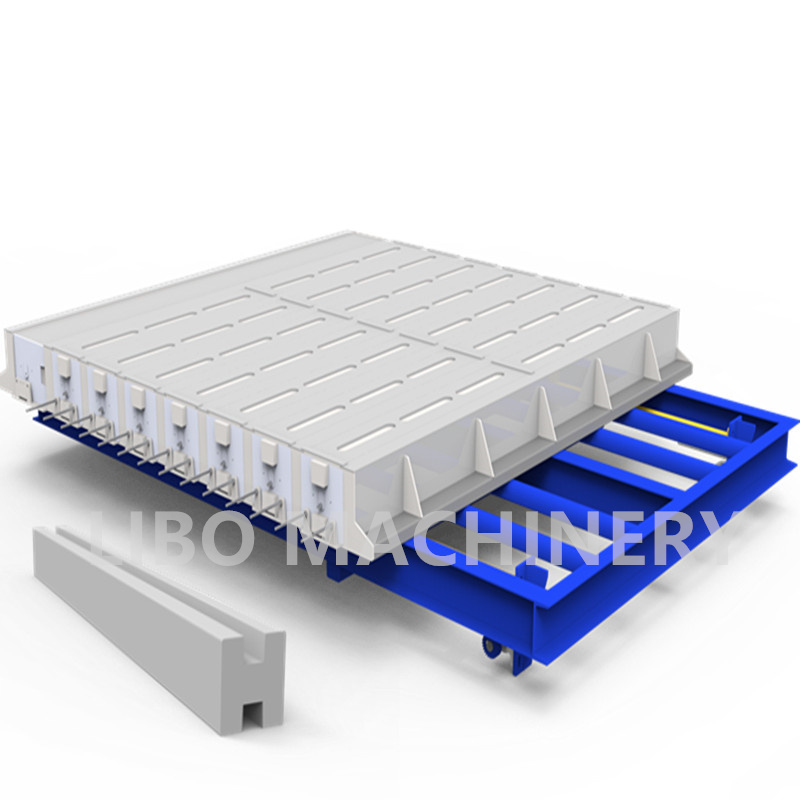

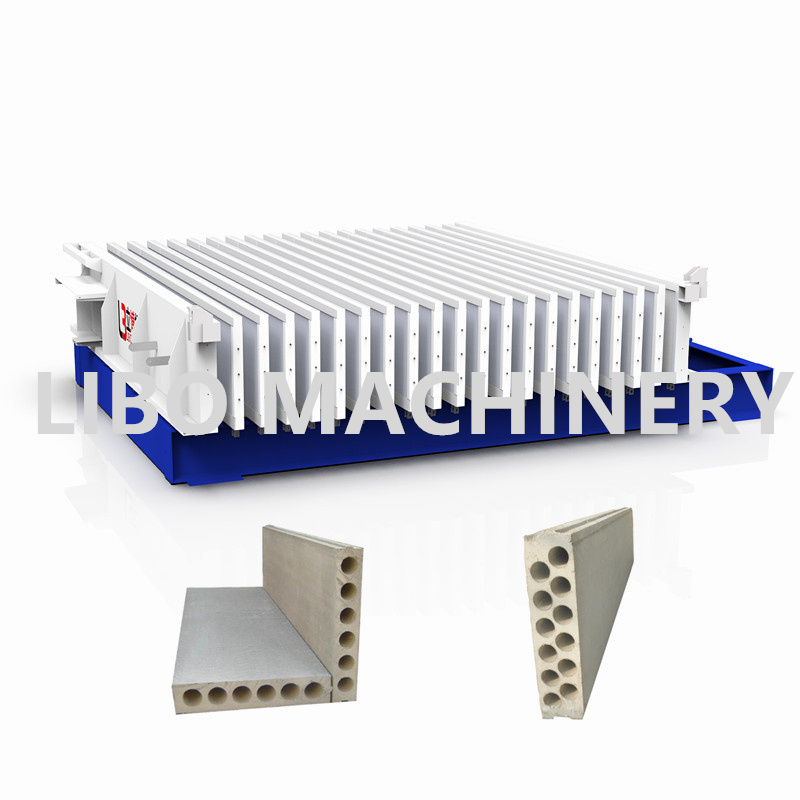

Automated Composite Wall Panel Equipment is a dedicated equipment for compounding materials to produce composite wall plates for composite wall boards. The working principle of automated composite wall board equipment is: mixing cement, gypsum, perlite, EPS and other materials in a certain proportion, and then The mixture is poured into the mold by the pouring system, and the mixture is evenly distributed through the vibration system. The equipment output can be customized. Usually, the number of molds is 40-60, and the characteristics are high. Due to the high density of the cement itself, most of the filling materials used are things like flour ash, scum, and pottery grains. The proportion is large. The production of cement wall plates is heavy. In order to reduce weight, the production line is equipped with a foam system. The composite wall plate produced by the foaming process meets the requirements of light and high -strength, and the equipment can be adjusted.

|

Libo Machinery Product Parameter Form |

|||

|

Order number: LB-Automation Composite Wallboard Equipment

|

Type: composite wall board

|

Vibration frequency: 1.2 (Hz)

|

Main vibration form: pouring formation

|

|

Whether the supply of cross -border export supplies: Yes

|

Custom processing: Yes

|

Molding cycle: 8-12 hours

|

Maximum pressure 5-12 (kn)

|

|

Working pressure: 0.4-0.8 (MPA)

|

Total power: 50KW-120KW

|

Alias: Automated composite wall board equipment

|

Brand: Libo Machinery

|

|

Material: high -quality steel

|

Transmission method: hydraulic electric |

The entire machine weight: 5-8 (t) |

Dimensions: 420*130*270 (cm) |

|

Place of origin: from China |

Uses: such as rural houses, farms and other places, it can effectively improve the safety and comfort of agricultural buildings. |

||

Production output:

The number of wall plates produced by automated composite wall board equipment depends on the model and production speed of the machine. Automated composite wall board equipment: a day a day, a mold of 36 square meters, increase the output method, to increase the number of molds.

Application field:

Compound wallboard applications such as playgrounds, gymnasiums and other places can effectively improve the safety and aesthetics of places. Such as shopping malls, hotels, hospitals and other places can effectively improve the safety and aesthetics of public buildings.

Delivery period:

It takes about 30 days to 45 days from production to delivery period. This is because our products are customized according to customer needs. Automated composite wall board equipment requires a certain production cycle to complete production and quality inspection to ensure that the product is the Automated Composite Wall Panel Equipment. Quality and reliability. During the production process, we will strictly conduct production and delivery in accordance with the delivery period agreed in the contract, and timely provide customers with feedback from the production progress and delivery situation to ensure that the customer's demand for the product is met.

show of power:

company advantage:

Our company's service attitude is good, and we always provide customers with professional and thoughtful services with customer satisfaction. We also pay attention to customer feedback and opinions and continuously improve service quality.

Summarize:

Automated composite wall board equipment is a mechanical equipment that is efficient, accurate, stable, time -saving, multi -functional, multi -functional, energy -saving and environmental protection, wide range of applications, high accuracy, easy operation, convenient maintenance, safe and reliable, and high degree of automation. One of the important equipment for production.