Automatic Ceramic Particle Wall Panel Machine

China Lido Machinery Automatic Ceramic Particle Wall Panel Machine custom supplier, automated pottery wall board machine price consultation, equipment uses energy -saving and environmentally friendly production technology, can reduce energy consumption and environmental pollution, and meet environmental protection requirements. As a professional manufacturer, Lingbo Machinery is willing to provide you with an Automatic Ceramic Particle Wall Panel Machine. We will provide you with the best after -sales service and timely delivery. And the production technology is relatively mature, the performance and quality of the equipment are stable and reliable, the quality of the production is high, and it has high market competitiveness.

Send Inquiry

China Lido Machinery Automatic Ceramic Particle Wall Panel Machine custom supplier, automated pottery wall board machine price consultation, equipment uses energy -saving and environmentally friendly production technology, can reduce energy consumption and environmental pollution, and meet environmental protection requirements. As a professional manufacturer, Lingbo Machinery is willing to provide you with an Automatic Ceramic Particle Wall Panel Machine. We will provide you with the best after -sales service and timely delivery. And the production technology is relatively mature, the performance and quality of the equipment are stable and reliable, the quality of the production is high, and it has high market competitiveness.

What is light wall board?

Lightweight wall plate is a new type of building material. It uses raw materials and other raw materials such as light material, cement, gypsum, cellulose and other raw materials. It has the advantages of light weight, high strength, sound insulation, insulation, fire prevention and other performance advantages. Lightweight wall plates can be used for the production of building components such as interior walls, exterior walls, partition walls, ceilings, and slabs, which can effectively improve the safety, comfort and environmental protection of the building.

Features:

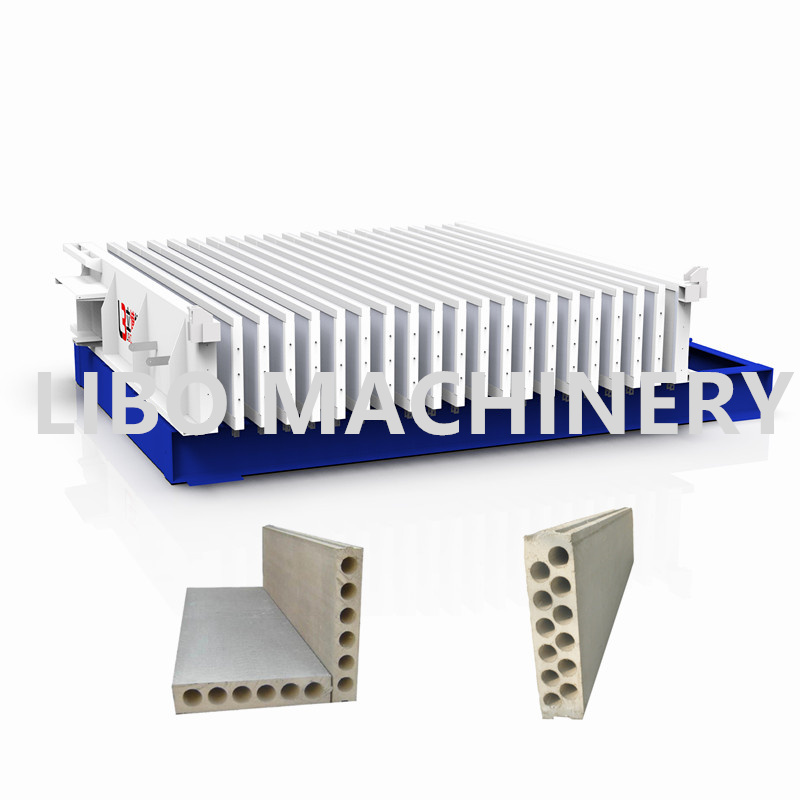

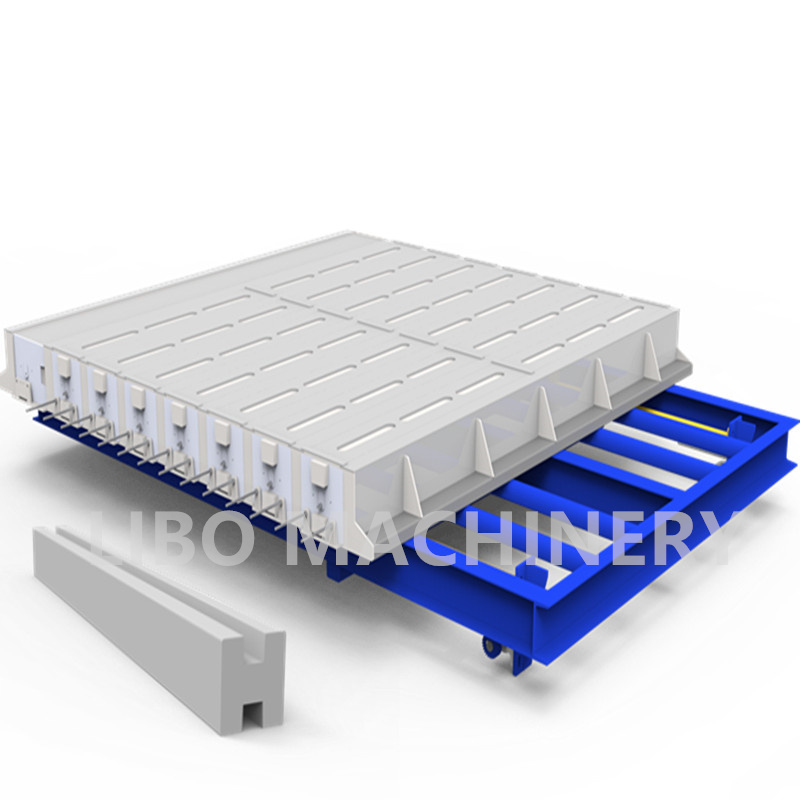

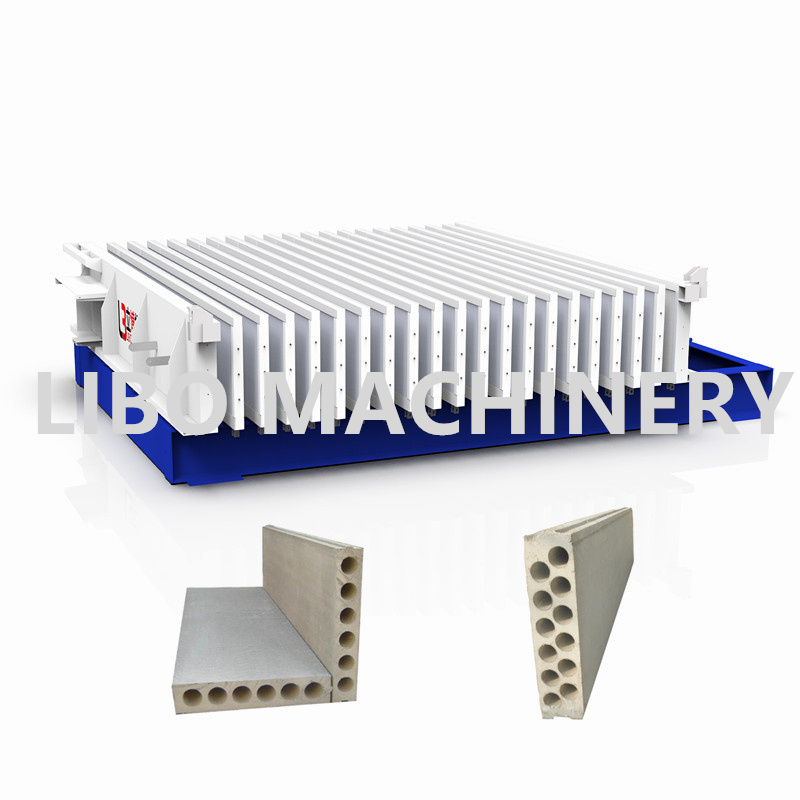

Automatic Ceramic Particle Wall Panel Machine is a special equipment for making ceramic materials for ceramic wall plates to produce ceramic septum boards. Because the cement itself has a long solidification time, it is usually 8-12 hours, and the temperature also requires the temperature. The equipment is equipped with the equipment. Energy -saving and environmentally friendly carbon fiber heating density, the cement itself is density, most of the filling materials used are things like flour ash, scum, pottery grains, etc. The proportion is large. Equipped with a foam system. The pottery wall plate produced by the foaming process meets the requirements of light and high -strength, and the equipment length and thickness can be adjusted. Due to the short solidification time of the ceramics, the entire production process is fast, the production capacity is relatively high, the automation of automated pottery wall board machine is high, the production efficiency is high, and the product quality is stable. benefit. Adopting advanced safety protection measures, such as safety doors, safety sensors, etc., can effectively ensure safety in the production process. The production of the pottery walls produced is heavy. In order to reduce the weight, the production line is equipped with a foaming system. The wall plate produced by the foaming process meets the requirements of light and high -strength, and the length and thickness of the equipment can be adjusted.

|

Libo Machinery Product Parameter Form |

|||

|

Order number: LB-Automated Ceramics Wallboard Machine |

Type: Ceramics partition wall board |

Vibration frequency: 1.2 (Hz) |

Main vibration form: pouring formation |

|

Whether the supply of cross -border export supplies: Yes |

Custom processing: Yes |

Molding cycle: 8-12 hours |

Maximum pressure 5-12 (kn) |

|

Working pressure: 0.4-0.8 (MPA) |

Total power: 50KW-120KW |

Alias: Automated Ceramics Wallboard Machine |

Brand: Libo Machinery |

|

Material: high quality steel |

Transmission method: hydraulic electric |

The entire machine weight: 5-8 (t) |

Dimensions: 300*400*150 (cm) |

|

Place of origin: from China |

Uses: such as rural houses, farms and other places, it can effectively improve the safety and comfort of agricultural buildings. |

||

Production output:

The number of wall boards produced by automated pottery wall boards depends on the model and production speed of the machine. Automated pottery wall board machine: One day, a mold of 36 square meters, increase the output method, to increase the number of molds.

Application field:

The application of pottery wall boards such as factories and warehouses can effectively improve the safety and durability of industrial buildings. It has the advantages of waterproof, fire prevention, durability, etc., and can effectively improve the safety and comfort of houses.

Delivery period:

It takes about 30 days to 45 days from production to delivery period. This is because our products are customized according to customer needs. Automated pottery wall board machines require a certain production cycle to complete production and quality inspection to ensure the product Quality and reliability. During the production process, we will strictly conduct production and delivery in accordance with the delivery period agreed in the contract, and timely provide customers with feedback from the production progress and delivery situation to ensure that the customer's demand for the product is met.

show of power:

company advantage:

Our company's brand is well -known and has a certain influence in the industry. We have also obtained a number of industry certifications and honors, such as ISO9001 quality management system certification, and China's environmental product certification.

Summarize:

Automated pottery wall board machines have the characteristics of high degree of automation, high accuracy, good stability, high production efficiency, wide application range, easy operation, convenient maintenance, safe and reliable, energy saving and environmental protection. It is a very good mechanical and equipment.